In today’s day and era food and beverage business requires more advanced technology tools to meet the market demands. In the past, ERP for food industry in the UK has become the gold mine for the industry to unlock the agility and actionable insights to compete.

Of course, no ERP solution will produce the desired outcomes. Selecting the top ERP software for the food business is necessary if you work in the food industry. Your ERP solution should include features that are appropriate for the particular operations; it should not require expensive customisations or time-consuming workarounds that may delay ROI. An ERP system help food companies in the UK to manage and improve the business operations from purchase, accounts, human relations, finance to production.

In this blog, we will talk about the roles of ERP systems in the food industry such as their benefits and how ERP impacts operations in the manufacturing industry of the UK. Before we get started with the benefits and the importances of ERP, it best to understand what challenges you could face in the food industry.

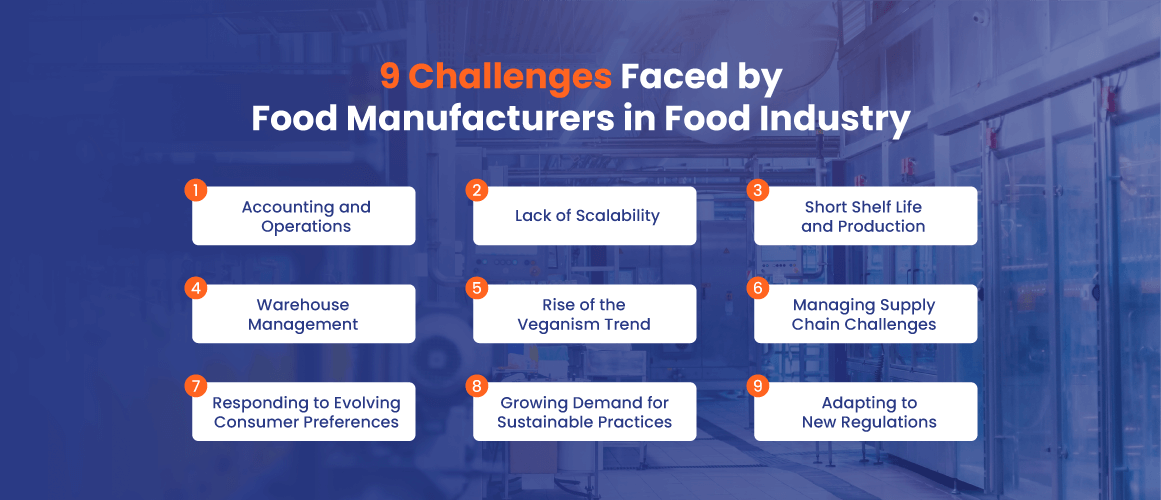

9 Challenges Faced by Food Manufacturers in Food Industry

Accounting and Operations

With low profit margins and rising raw material costs, food manufacturers are finding it hard to stay in business. You can start by streamlining the business operations with the best ERP system for food processing. Integrating an ERP solution with inventory, sales, and purchasing eliminates human errors, including double data entry and many other tasks that are manually done by the accounting department.

Lack of Scalability

Food and safety regulations require these companies to comply with the regulations. An ERP software for food manufacturing with an integrated quality control function will give control of the supply chain and quality control data.

Warehouse Management

Efficient warehouse management is necessary for food and beverage manufacturers to make sure food safety, brand value, and business growth. Stock tracking is not only crucial but essential to satisfy customer demand. If there are fewer items in stock, customer demand is not met. A state-of-art warehouse management system plans and optimises inventory-related processes.

After reading all the above challenges, you might have encountered a few for sure. Let us understand further what ERP is and how it benefits the food and beverage manufacturing business.

Rise of the Veganism Trend

This is a sign that more people are becoming aware of the negative impacts of animal-based diets on their health, the environment, and the welfare of animals. The health benefits associated with a vegan diet, such as reducing the risk of heart disease, cancer, and diabetes, are well-documented. The trend of veganism is growing rapidly and its positive effects on health, the environment, and animals are undeniable. On one hand, where it is beneficial for human health, and on the other hand, it is a big challenge for the food industry.

Managing Supply Chain Challenges

From sourcing raw materials to managing distribution channels, the industry faces many supply chain challenges. Companies must make sure that their supply chains are efficient and cost-effective to remain competitive.

Responding to Evolving Consumer Preferences

Consumers are becoming more health-conscious and are demanding healthier, more natural products. Companies must be able to respond to these changing preferences so that they remain relevant.

Growing Demand for Sustainable Practices

The food and beverage industry has been under a lot of pressure to adopt sustainable practices, such as reducing energy consumption, minimising food waste, and using locally sourced ingredients.

Adapting to New Regulations

The industry is subject to an ever-changing regulatory environment, which can be difficult to maintain. Companies must ensure they are compliant with the latest rules and regulations in order to remain competitive.

What is an ERP system, and Why ERP is Important in Food Production?

ERP stands for Enterprise Resource Planning and alludes to a product framework for business executives. An ERP system allows food organisations to manage and streamline their business processes – from buying, bookkeeping, finance, human relations, and creation to coordinated factors. In short, ERP is the product that keeps your business ready. Requesting untouched substances, managing orders, overseeing, and improving recipes, charging, creation arranging, and much more.

ERP solutions should not require any third-party software in key regions, and they are suitable for providing all divisions and players in a food organisation with reliable information. What sounds great in principle guarantees quick and effective cycles by and by when a client request comes in by means of a web-based shop or EDI, the system consequently confirms the stock accessibility, tells the creation scheduler, and starts product picking. With no media disturbances or interferences.

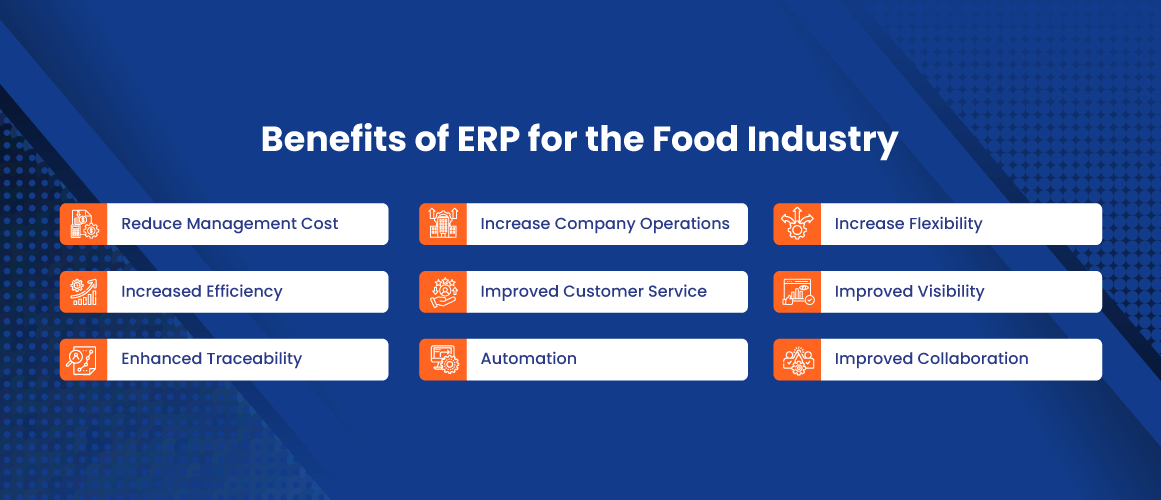

Let us Understand the Benefits of ERP for the Food Industry

Food manufacturing business owners are always looking for a way to improve their conversion rate. However, choosing the best ERP software for the food and beverages industry means growth in business performance, reinforcing company growth, and reducing working capital.

Reduce Management Cost

Because of ERP systems for food manufacturers, are getting a general view of all the operations. So, they can quickly identify where they need to reduce expenses and where to increase costs. This will help the business stand out from the competitors.

Increase Company Operations

Other than cost-cutting, food companies are able to find ways to increase efficiency with ERP solutions. According to research, ERP software facts, companies that have applied ERP reduce process time and increase collaboration with real-time data of all which is imperative to optimisation. This helps the business run smoothly.

Increase Flexibility

96% of the companies experienced an improvement in their processes after implementing the ERP system. As ERPs are flexible, companies use a specialised ERP that works for individuals, products, and goals. As the business grows, using a system that can scale and evolve with a company is ideal.

Increased Efficiency

ERP helps to streamline operations and reduce duplication of processes and data entry, resulting in improved production efficiency and cost savings.

Improved Customer Service

ERP systems enable food businesses to provide better customer service by providing up-to-date information about orders, inventory levels, and delivery times. This helps customers make more informed decisions and ensures that orders are processed quickly and accurately.

Improved Visibility

ERP gives managers a complete view of the entire production process, from the ordering of raw materials to the production and delivery of finished products. This allows for better decision-making and improved customer service.

Enhanced Traceability

ERP systems enable food processors to track their products from start to finish, ensuring that food safety regulations are followed, and that the quality of the food is consistent.

Automation

ERP systems can automate many tasks, such as inventory management and product tracking. This reduces the burden on staff, freeing up resources for other tasks.

Improved Collaboration

ERP systems enable collaboration among different departments, as well as with suppliers and customers. This helps to foster better relationships and improve communication.

Want to Start your Digital Transformation Journey and Implement SAP Business One with your Business?

What Role Does ERP Play in the Digitalisation of Food Companies?

The food market depends on the use of digitalisation and ERP to assist with dealing with their supply chain, further develop agreement, and to increase productivity.

Food companies can improve the nature of their products by working with digitalisation and ERP, which provide a wide range of data that can be used for decision-making.

ERP and digitalisation can also assist food companies in managing their constant inventory control. By creating a digital inventory and obtaining data on the whereabouts of their belongings, this ought to be achievable. ERP and digitalisation are further tools that food companies can use to increase productivity. Food businesses can reduce the time it takes to complete tasks by adopting digitisation and ERP. This ought to be achievable by using Silver Touch ERP for food processing and automating tasks.

The use of the digitalisation and the ERP can help food organisation reduce how much assets they use during the time spent maintaining their business. This should be possible through computerising assignments and using Silver Touch ERP software for food and beverages.

Must-Have ERP Features for a Food Company?

Real-Time Inventory and Stock Management

Although it may seem obvious, knowing what you have on hand and being able to rely on the fact that your figures are generally state-of-the-art are significant advantages in the food and beverage industry. Under these conditions, finding yourself short on a fundamental patch at an inconvenient time might be a nightmare come true and seriously impair your ability to fulfil your plan fulfilment and delivery responsibilities.

ERP solutions designed for the food and beverage industry control the power of mechanisation and mix to ensure that your stock levels are accurately displayed at the connection point. They also make it much easier to find what you are looking for because they capture more information than just quantity. With a high-level ERP solution, you can find out the location of a certain package, when it was received, when it ends, and much more.

Shelf Life and Expiration Management

Length of usage and executive lapse are strongly related to stock control since your methods for determining the appropriate quantity of stock to employ in the process are what really matter. First expiry, first-out (FEFO) strategies are proven to reduce waste and help you make the most of your purchases, therefore your ERP should help you implement them.

Likewise, realising that ruined fixings address a food handling risk, your system should raise an alert when some shipments are nearing the end of their useful life. This way, they can be used quickly, if time permits, or they can be completely removed from stock to avoid finding their way into your finished product. Better customer experiences should result from this, since they would be able to enjoy freshly prepared cuisine.

Recipe and Formula Management

The recipes that power your products are key to your success, so you need to invest in modern recipe boards with tools that ensure precise levelling, timing, blending techniques, cooking cycles, and much more. In specific areas of the food and refreshment industry, equations can turn out to be very mind boggling, however a genuine food industry ERP will want to deal with the subtleties and granular subtleties of even your most difficult setups.

The implementation of programmed unit change is highly recommended in an ERP system for food production since it is an amazing time-saver when it comes to adjusting and monitoring amounts. You should also look for the ability to work with smart sensors, since you may need to closely monitor features like temperature, consistency, and fill level to make sure your products meet your own standards for perfection.

Directly connected to the recipe, quality control is what the board provides, and we all know how important it is to customer loyalty and brand recognition. ERP software for the food business that is worth its salt should have features that improve the quality control process and ensure that your production lines produce products that will please customers.

A strong ERP system may assist you in identifying and capturing deviations from internal policies so that no subpar products evade scrutiny and make their way to final consumers. This is achieved by letting you establish your own quality triggers. Additionally, you can create a number of inquiry scenarios that will help to ensure that everyone on your staff is aware of what has already been confirmed needs to be verified, maintaining consistent product quality, and satisfying customers.

Recognisability and Review Availability

Achieving complete recognition both in and out of your store network is an absolute must in the current food and beverage manufacturing landscape. On the other hand, it is fundamental for sanitation as well as important for customer confidence in the simplest of your products.

No business needs to confront a crisis review circumstance, however with the right food industry ERP programming on your side, what could somehow with the right food industry ERP programming on your side, what could somehow be terrible in significantly more reasonable.

Strictly designed stage like Sliver Touch software for food distributors likewise make finishing the essential withdrawal desk work and interchanges simple, as a work process can be laid out in advance and certain means can be robotised. It can also consequently plan your own reviews, ensuring they ae regularly and appropriately work on another protection measure.

Allergen Management

As for discernibility, keep in mind that further thought will be necessary if your company uses any additives that raise sensitivity issues, especially those that appear on lists of hazardous materials that are distributed by the UK government and the U.S. Food and Drug Administration. Regardless of how long you have any of those food variety in stock, you should keep them separate from other ingredients and take care of the surfaces they come into contact with. Food industry-explicit ERP frameworks have functionalities devoted to these significant issues, assisting you with guaranteeing that you safeguard delicate end buyers and keep away source of item withdrawals, sound allergens the bound can likewise assist with setting aside your business cash, decreasing the possibilities that you’ll need to pull items from racks without regard to you.

What do Food Companies Need to Consider When Choosing ERP System?

An incredible ERP for food processing industry will have the following:

Powerful, Real-Time Analytics

The importance of information in almost every aspect of a business cannot be overstated, especially in one where task productivity and profitability are heavily dependent on numbers. However, in order to assess the performance of your organisation, it is not necessary to obtain this data in its entirety. You should have the option to decipher it such that it sounds good to you and your group so you can improve, more educated business choices. An ERP that allows ongoing analysis can be helpful when gauging the performance of a different product or reviewing quarterly marketing forecasts. An ERP specifically designed for the food industry will offer the level of customisation you desire when it comes to extracting data, categorising it, and turning it into meaningful insights.

The ERP you select ought to make it simple for you to distinguish patterns, estimate, and gain a superior comprehension of how your business is performing.

Incorporated Quality Checking

Exchanging between screens or projects while on the floor can cause disruption for workers. While you are observing information that influences your quality practices, it is essential to have data that is coordinated and precise.

Selecting an ERP that enables users to view high-quality data and insights in a single screen simplifies the shop floor. It is easier for labourers to screen because they can view consistent information on a single screen. Similarly, workers can predict problems before they arise based on current information and reliable data, provided that they have quick access to this information in a concise view. Then, they can act quickly to address any problems before they get out of control.

Let’s say, for example, that your company makes string cheese. The ERP program will identify any elements in the production line that can cause consistency problems and provide you with important details on the most effective way to address the problem before it gets worse. Any organisation that manufactures food should have access to an ERP program that enhances the exchange, understanding and updating of information that is inclusive.

Warehouse Management System (WMS)

Keeping daily operations within proper limits is the way into an effective plant. A full understanding of jobs is essential, ranging from following massive quantities like order and part numbers to organising the board and reordering procedures. Floor tasks and the organisation may be hindered if this information is not appropriately associated or transmitting.

Choose an ERP that is applicable to the case and has WMS ability. The ability to view this basic data both initially and thoroughly promotes the development of activities. To streamline activities, many organisations use a combination of an ERP framework and a WMS framework. On the off chance that your ERP has WMS usefulness, issues with passing information between frameworks are limited and significantly more proficient.

Scalable Features to Grow with You

Despite the fact that executing an ERP solution is a tedious endeavour, and time is valuable in the food industry. Around 30% of organisations who conduct another framework report that it takes more time than assessed. Subsequently, the ERP you select ought to be adjustable and versatile to stay aware of your ever-changing business.

As your company grows as a result of the updates brought about through the use of the ERP solutions, expansion should be possible. Adding additional customers and clients, expanding into new locations, managing several organisations, and granting reps remote access on various devices are typically signs of development. Utilising an ERP application that can deal with those necessities is essential to keeping up with efficiency and net revenues.

Cloud ERP, On-Premise ERP, Hybrid ERP? What is the Best ERP for Food Companies?

There are multiple operating models of ERP that may be a fit for your business. Which one is the best?

- Cloud-based ERP System

- On-premise ERP software

- Hybrid ERP Software

Considering the current market, everything seems to favour the cloud-based system. Regardless of how fascinating the cloud-based system sound, there are various elements that should be thought about while figuring out which ERP model best suits your business. We should see:

Multi-tenure

Committed cloud arrangements capability in a multi-occupancy climate with shared assets conveyed over the Web. Through monthly membership fees and instant administration delivery, which help prevent upfront capital consumptions, you can benefit from a multi-occupancy structure. For simple programs that do not require customisation, multi-occupant programming is suitable; if your business is private, this is the best option for you. In any case, operating your ERP in a private cloud environment might be a preferable option if your company is a medium-sized or large enterprise with more complex business operations.

Framework Execution and Speed

Each ERP execution takes time and requires careful preparation, however with regards to speed of organisation, cloud ERP is the undisputed champ. You may definitely run your ERP system across different geographies, auxiliary, and offices with the use of the cloud. Similarly, cloud ERP frameworks often deliver preferable execution over their on-premises partners due to the concealed design. They adapt well to your business needs since they are designed for optimal organisation execution, improved application accessibility, and enhanced execution.

Network Availability

Despite the fact that network availability is working around the world, there are a few organisations that are forced to endure a lack of availability due to their geological areas. In such cases, facilitating ERP in the cloud probably will not be feasible, and that makes an on-premises arrangement the smartest choice. By surveying the presentation and dependability of nearby organisations, you can show up at a money saving advantage examination that demonstrates on-premises as the best sending model.

System Updates

On-premises ERP solution customisations are attached to your ongoing programming organisation; they are difficult to recover with new adaptation discharges. As new forms of ERP are delivered, your prior customisations will be deleted, and your IT group should begin without any preparation. This is one of the principal motivations behind why many organisations try not to redesign their on-location ERP programming and settle for obsolete innovation. In contrast, cloud ERP arrangements are constantly redesigned by the supplier so you can be sure you are continuously using the most recent, most advanced version of ERP programming.

Information Security

The cloud could not be an option for projects involving the government or the financial sector. Only in rare occasions can organisations that need complete control over their systems and data due to the highly demanding nature of their business use the cloud for their applications. In such cases, private or mixture mists might be a choice: if the business information is excessively basic, you can pick a confidential cloud, yet to protect specific applications and cycles, then crossover cloud will assist you with keeping your basic information secure.

Costs of the ERPs

Normally, on-premises ERP frameworks require extensive knowledge of equipment, servers, and devices to run them. We continue to hear that the cloud is a less expensive choice for introducing ERP programming. For cloud-based ERPs, beginning expenses are much lower as you just arrangement the necessary foundation, saving significant expenses. So, if you are a beginning up association, have an occasional business, or have put negligibly in IT, cloud ERP will work out to be less expensive. Such organisations can rapidly get to cutting edge equipment without putting resources into a single server.

Tips to Implement ERP Software in Food industry

These are some of the basic tips on how food and beverage companies should tackle the ERP system.

- From the beginning, involve everyone on the board, including your administration. Learn more about what they like and provide them the choice to make a choice. As a result, you take responsibility while ensuring that the arrangement includes the facts from the current cycle.

- Make a clear strategy for execution: describe the project’s assets, time, scope, budget, and nature so you can compare it to your requirements. Use the centre business fields and the previously characterised centre cycles as a general guideline.

- For a quick and effective movement, information must be ready, tidied up, and changed over. Since this holds true for both dominant and interchange information, you should prepare that take enough time into account. Maintain the highest priority when it comes to updating the non-moved information file!

- Excellent documentation is essential from the outset. This starts with a specific prerequisite and continues all the way to documenting the requirements for the new framework regarding burden regulations.

- Explain the obligations and ensure everybody knows that the presentation of the new framework is a high-level issue.

- Test the framework before you go live, preferably beginning with one subarea. On the other hand, you could keep your heritage framework running in line for some time.

- Plan for advancements. At times sensible changes and additional items just come up during the execution stage.

Why SAP B1 is the Best Choice for Food Manufacturers?

SAP Business One is a powerful tool and best ERP solution for the food industry, as it offers a range of features to help companies gain greater control over their operations and increase efficiency. The following are some characteristics that are particularly advantageous to the food industry:

- Recipe management enables your organisation to fabricate item variations utilising various recipes.

- Improved item reviews through the entire store network.

- Stock administration through the total creation, bundling, and circulation cycle.

- Materials Requirements Planning (or MRP) provides a variety of preparation and estimation of food items.

- Naming of bundled food varieties that are consistent with the Product Traceability Initiative (PTI) and other food handling rehearses.

- Stockroom the executives that track forward, in reverse, and on-request item developments.

- SAP Business One benefits the food business in more ways than one remembering for the duration of the conveyance of items, cost effectiveness, production network responsibility stretching out from the merchant to the client, lastly, consumer loyalty.

Simplify your operations with SAP B1 Food and Beverage Software

With the changing customer expectations, several SMEs and startups from the food manufacturing industry have turned into implementing the best ERP for food manufacturing like SAP Business One. This has helped them to automate their processes and resolve the key challenges faced by the food and beverage industry.

As an SAP B1 partner in UK, Silver Touch has enabled many food processing companies in UK to transform themselves with our digital technologies and solutions using SAP ERP. With the help of our experts, customers are equipped to manage inventory, supply chains, and material procurement.

Do you want to implement effective food ERP solutions into your food manufacturing business in UK? Contact us today.