The manufacturing sector is one of the biggest contributors to the growth in the world economy. A customised manufacturing ERP software is important to ensure the seamless performance of operations and improve the sector’s capability to add more value to the country’s development. In the US alone, there are over 12 million manufacturing workers. It shows the importance of ERP solutions in this sector.

Manufacturing ERP is designed to leave an impact on the entire operation. Therefore, it is necessary to conduct an extensive study of existing processes and workflow. You can improve the overall performance and bring the desired outcome by implementing automation in your manufacturing company thanks to ERP solutions. But then, you need to focus on the right implementation because even a slight lapse in selecting the right ERP solution in your business system can make the entire process fail.

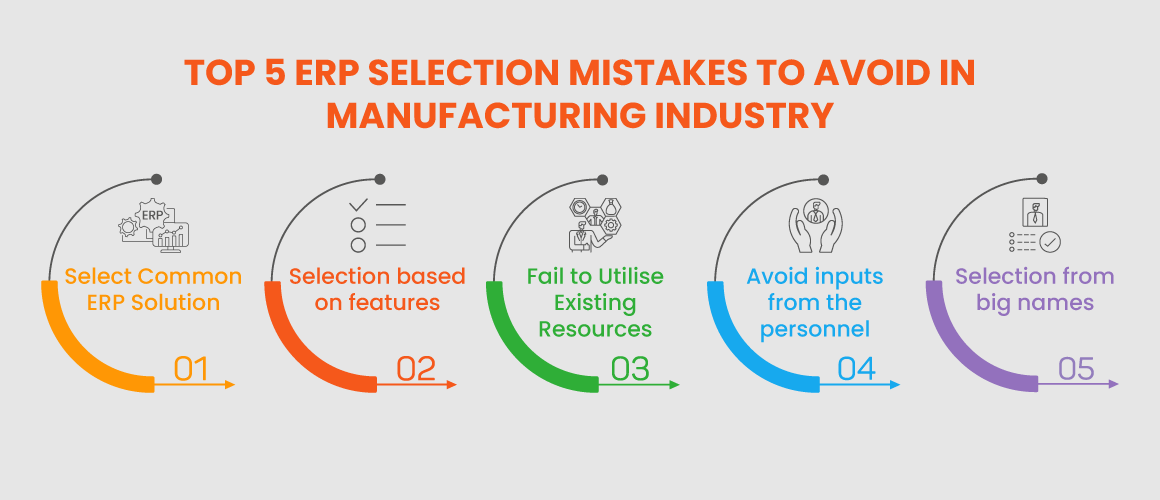

In this blog we will let you know 5 most common erp selection mistakes of project managers to avoid while deploying the manufacturing ERP software.Top 5 ERP System Selection Mistakes to Avoid In Manufacturing Industry

1. Do Not Select Common ERP Solution

It is fairly possible that project managers get tempted to select the ERP solution that runs seamlessly in various domains. However, here it is necessary to select an industry-specific solution. In other words, you should select the manufacturing ERP, an ERP specifically designed for the manufacturing sector, for your company. What’s more, when you hire ERP software developers, make sure that they have a vast experience of developing industry-specific solutions that suit your business needs.

2. Do Not Select ERP based on the Features

This is another common erp selection mistake committed repetitively by the management of the company. Mostly, company selects the ERP software on the basis of features. But, most of its features are of minimal or no importance for the manufacturing unit. Therefore, it is necessary to choose an ERP system that provides a straightforward and effective solution to all your manufacturing processes. Remember, an ERP solution is designed to simplify the process and improve productivity. Don’t get dazzled by interesting features, remember your workers want a system that makes their life easier and works efficiently.

Also Read- ERP And Digital Transformation Go Hand in Hand3. Do Not Select if it Fail to Utilise Existing Resources

When you opt for an ERP system, you need to make sure that it covers existing resources and works seamlessly with them. The ERP solution provider can modify the manufacturing ERP software to improve productivity by combining ERP features with existing resources. It can save your cost and enable you to get a higher ROI in a short period by unleashing the potential of your business.

4. Do Not Select if it Avoid inputs from the personnel

This is also one of the most common errors while implementing an ERP solution in the workplace. Usually, the management tends to avoid the inputs received by the personnel who are going to utilize this solution. It results in a lack of interest in employees and complex workflow even with ERP software in place. You should involve the employees who will be directly impacted by the ERP solution to get a user-friendly design and a better acceptance of the ERP system at the workplace. All change is disruptive, so it is important to get your workers, who ultimately will use the system on a day-today basis, to support the selection of the new platform. This negates any potential ‘blame culture’.

5. Do Not Select from Big Brands Only

This is the most common mistake. The company wants to select the most famous brand for implementing ERP software in their manufacturing company. You need to keep in mind that though you have selected a reputed ERP software developer in UK, it is better to find whether he is capable of delivering the most suitable solution for your manufacturing company. At times, big names may not meet your business needs effectively because of a lack of customization options and generic ERP solutions.

It is fair to mention that this is the right time to embrace the ERP transformation in your manufacturing company. You can make the most of customized ERP solutions in UK by overcoming these common mistakes and take your business to the next level.

Wrapping Up on Common ERP Selection Mistakes in UK

The manufacturing sector is thriving at a rapid pace to meet the growing requirements of various products globally. It further gives rise to competition, and SMEs find it difficult to cope with the ever-changing business scenario. Tailored ERP solutions remain handy for manufacturing companies irrespective of their scale and size. You need to find a reputable ERP solution provider in UK who can come up with the most suitable ERP software solutions for your business.

Silver Touch Technologies UK is a renowned manufacturing ERP software developer. As a reliable, experienced and and gold certified partner of SAP in UK, we offer SAP Business One ERP solution to manufacturing companies in UK. If you wish to reduce cost and wastage by improving the performance and efficiency of your employees, just drop us a line at info@silvertouchtech.co.uk. Our experienced ERP software developers/professionals will get back to you soon with a comprehensive ERP implementation strategy for your business as per your business need.

ERP Software Services – Other Resource

- ERP Benefits for Manufacturing: Why SAP B1 is the Best ERP Solution?

- How SAP S/4HANA Accelerates Innovation in the High-Tech Manufacturing Industry?

- 6 Ways SAP Business One Improves Manufacturing Processes in 2022

- 9 Stages of Successful SAP ERP Implementation

- Reasons Why You Should Choose ERP Software instead of Accounting Software

- 7 Smart Cost Strategies for ERP Selection